When to Use High Density Polyurethane Foams Like Poron and ISOLOSS™

High-density polyurethane foams, as their name implies, are a particularly dense type of foam that is commonly used across multiple industries. Some of the more common uses for high-density polyurethane foam include furniture pads and athletic gear, but they also make incredibly durable and effective foam gaskets because of their low compression set, resistance to a number of chemicals, and fabrication options.

Two of the more commonly used high density polyurethane foam gasket materials on the market are Poron® (by the Rogers Foam Corporation) and ISOLOSS™ LS by 3M™. Both are comparable in terms of price and performance, and both make excellent options for gasketing applications and other foam needs.

What is Poron® Foam?

Poron is a type of high-density polyurethane foam that is low-outgassing, non-fogging, non-corrosive, and is available in a wide range of options for versatile applications. Poron foam is open-cell, allowing it to maintain its shape after constant pressure is applied to it. Its viscoelastic properties are what make it an ideal foam type for gaskets, as it maintains its strength and integrity for long periods of time when compressed.

What is ISOLOSS™ LS Foam?

ISOLOSS LS is a micro-cellular, open-cell foam manufactured by 3M, and it makes an excellent alternative to Poron for gasketing, sealing and other applications. This is because the foam shows remarkable resilience and longevity when compressed. The foam is also highly shock absorbent and has a high level of flame and chemical resistance.

Why Use High Density Foams?

High density polyurethane foams like Poron and ISOLOSS LS are effective choices for gasketing and sealing because of the benefits they provide:

Large range of deflection forces

Low compression set

Excellent impact and vibration resistance

Chemical stability and resistance

Resistance to water and moisture

Performance at a wide range of temperatures

Will not become brittle or crack in low temperatures

Can be used with various adhesives and tapes

Non-slip

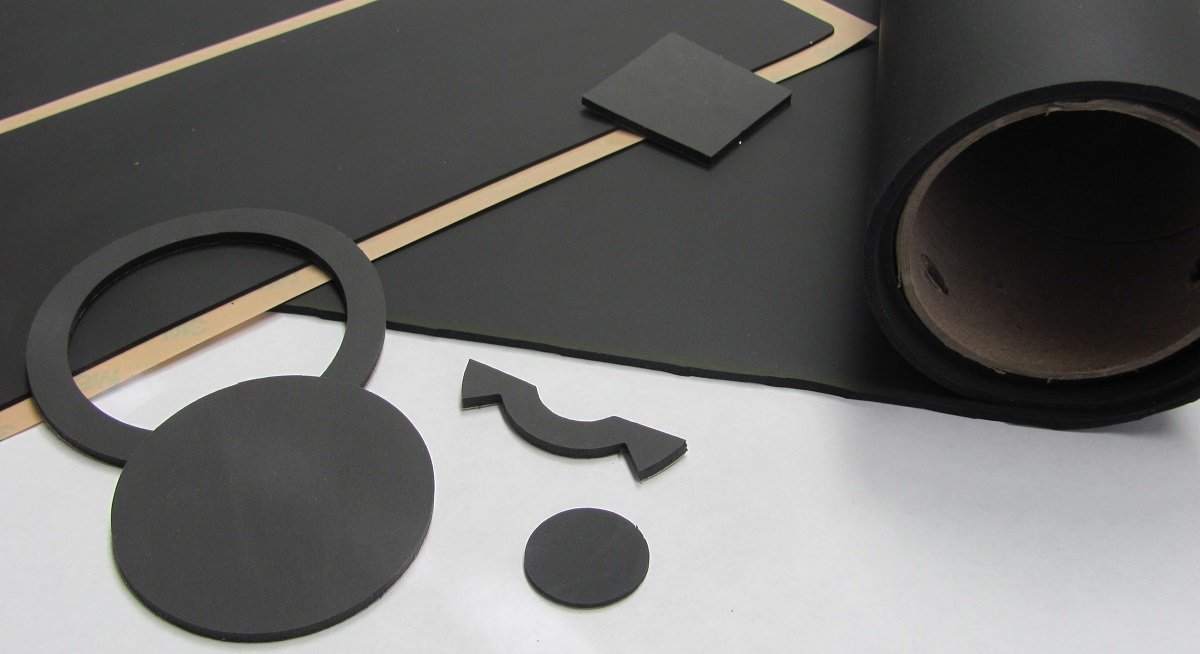

Easy to manufacture into custom shapes and sizes

Low outgassing and non-fogging

Flame retardant without using additives

What Are the Applications for High Density Foams?

Besides gasketing and sealing applications, high density foams like Poron and ISOLOSS LS can be used in applications that require:

Gap filling

Vibration isolation

Sound dampening

Light blocking

Padding and cushioning

Shock absorption

EMI and RFI shielding

Part and component mounting

High-density polyurethane foams should not generally be used in outdoor applications or those that are expected to be exposed to standing water, as the water may cause wicking. High-density polyurethane foams are also not suitable for extremely high or low temperatures. Try to avoid temperatures below -20°F, which can cause the foam to stiffen, and temperatures above 158°F. In these cases, it is more ideal to use materials like EPDM, silicone, and neoprene.

Looking for a high-density polyurethane foam for gasketing, sealing, or any other application? We can help. We custom manufacture gaskets and PSA tapes using a wide range of foam types and can help you choose which is best for your application. Get in touch with us today.