Adhesive Transfer Tapes vs. Double-Sided Tapes: What’s the Difference

What is the difference between adhesive transfer tapes and double-sided tapes? While both are considered great options for a variety of applications, can be custom cut to create unique parts, and are available with several different adhesive types, there are key differences between the two types of pressure sensitive adhesive tape options. Choosing the right PSA tape for your application is important.

What are Double-Sided PSA Tapes?

Your typical double-sided tape construction is comprised of the following:

A carrier, typically made from a flexible film.

A thin coating of pressure sensitive adhesive that is applied to each side of the carrier.

A release liner.

Double-sided PSA tapes are made with the adhesive layer on both sides of the carrier and wound on a disposable release liner. Thin film and paper carriers provide additional dimensional stability for easy tape handling and application. Varying the carrier type allows you to meet your specific needs. For example, tissue carriers allow for easy hand tearability while polyester carriers increase dimensional integrity.

The most common PSA adhesive types on these tapes are a wide range of acrylic adhesives, natural or synthetic rubber adhesives, or silicone adhesives. If required, different adhesives can be used on opposite sides to optimize the bond to dissimilar materials. All double-sided tapes come with either a paper or film release liner that is used to separate the adhesive on the roll

Double-sided foam tapes, which feature a thicker carrier material, can also be used to fill gaps between the two surfaces and provide higher strength bonds. They can also often be used to join two materials or act as seals, vibration dampeners, etc. Som double-sided foam tapes can even replace rivets, spot welding, and mechanical fasteners.

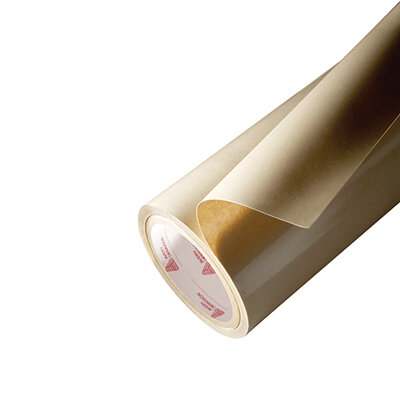

What are Adhesive Transfer Tapes?

Your typical adhesive transfer tape construction is comprised of a thin, uniform coating of unsupported pressure sensitive adhesive that is applied to a release liner.

Adhesive transfer tapes are made with pressure sensitive adhesive laminated directly onto a special release liner. After the tape is placed onto the desired surface, the liner is removed exposing the adhesive face for bonding to the secondary surface. The most common PSA adhesive types for these tapes are a wide range of acrylic adhesives, natural or synthetic rubber adhesives, butyl adhesives, or silicone adhesives.

Release liners come in a wide range of paper and film options in differing weights to meet your specific needs. Adhesive transfer tapes are most often used when bonding thin or flexible materials since they can be coated in thicknesses of 0.002” or less and do not retain significant dimensional stability. Their design also lends itself to higher temperature resistance. Adhesive coat weights can be customized on adhesive transfer tapes based on the application for increased strength or tack, and the tape can be die-cut to any shape or size. Adhesive transfer tape options include:

Low surface energy bonding adhesive transfer tapes

High temperature resistant adhesive transfer tapes

Food grade adhesive transfer tapes

High strength adhesive transfer tapes for nameplates

Adhesive transfer tapes and double-sided tapes are also used to speed up the manufacturing and assembly of products because of how simple they are to apply. They are a great way to speed up production and reduce the cost of manufacturing.

Which is Right for Your Application?

Whether double-sided PSA tapes or adhesive transfer tapes is the right choice for your application depends on many factors:

The surfaces and surface area to be bonded

The roughness and/or irregularity of the surface

The geometry of the surface (i.e., if it has sharp edges, contours, or curves)

Substrate thickness or gaps need to be filled

Operating temperature ranges

Exposure to chemicals, solvents, fuel, moisture, UV, etc.

These are just some of the variables to consider. If you need help choosing between adhesive transfer tapes or double-sided PSA tapes, we can be your guide. Get in touch with Engineered Materials today to talk about your project and what’s possible.