Very High Bonding Tape and its Applications

The versatility, ease of application, and sheer strength of very high bonding (VHB) tapes make them an ideal replacement for metal fasteners and other adhesive types used in applications across multiple industries. VHB tapes are just one of the types of pressure sensitive adhesive (PSA) tapes that can be used, and their unique qualities make them the smart choice when bonding different substrates.

What is very high bonding tape, and what are the best applications for it?

What is Very High Bonding Tape?

Very high bonding tape is a high strength double-sided foam tape meant to be used as a permanent bonding solution. Made from an acrylic polymer material, VHB is highly viscoelastic, allowing the tape to maintain its strength and elasticity while stretching across nearly any surface.

VHB tapes can be used in indoor and outdoor applications where components are meant to be held together permanently. It is very difficult (but not impossible) to separate two surfaces that have been attached with VHB tape. The most notable feature of VHB tapes is how they build strength over time. In most cases, with proper application, VHB tapes will achieve 50% strength in as little as 20 minutes. Within 24 hours, the bond will hold at 90% strength, achieving full strength after 72 hours.

VHB tapes are designed to maintain a strong bond for years.

The Benefits of Using VHB

Besides a strong bond that lasts years, there are many reasons why 3M™ VHB™ Tapes should be used over screws, bolts, and other metal fasteners.

Versatility of Use

VHB tapes create a strong bond across many different types of substrates, being able to join materials ranging from aluminum and steel to glass, plastics, and even painted and powder-coated surfaces. Since the tape is double-sided, dissimilar substrates can also easily and securely be bonded together.

Different 3M™ VHB™ Tapes have varied levels of adhesion to different types of materials. Some are more suited for metals, while others more easily bond plastics and painted surfaces. These are some of the VHB tapes we supply to our customers.

VHB tapes are also easy to fabricate into custom shapes and sizes, including using die-cutting to create custom pieces of tape that can be used to quickly attach components during manufacturing and assembly.

High Resistance to Environmental Factors

VHB tapes offer a high level of resistance to many common environmental factors across multiple industries, including:

Extreme temperatures and heat

Shock and impact resistance

Water and moisture resistance (can even be used to create a watertight seal)

Superior dynamic load resistance

UV and humidity resistance Vibration resistance and dampening

VHB tapes are an excellent option for outdoor use as they are resistant to weathering and remain durable across their entire lifespan.

Faster Manufacturing and Assembly

Attaching metal fasteners often requires multiple components, special tools, and far more time than using VHB tape die cut parts. Welding requires tools, specialized skills, and post weld finishing to achieve the same effect. Over time, galvanic corrosion can occur when differing substrates are joined. Liquid adhesives are messy, difficult to meter, can off-gas, hard to clean up, and often result in uneven application of the adhesive. VHB tapes have none of these issues. They are simple to use, quick to apply, and do not require any special tools or skills. Adhesive application is consistent across the entire bond line, and they add very little weight to the end product. They can be applied on rough, curved, and uneven surfaces, leaving little to no visible tape after application.

All these benefits come with a faster, more streamlined assembly process that will cut down the amount of time it takes to finish each product.

Applications for Very High Bonding Tape

VHB tapes are used in a large number of applications because of their versatility, ease of fabrication, and high strength. While they aren’t ideal for all applications, they can be used as a replacement for rivets, screws, bolts, welds, and liquid adhesives in many different types of products.

Electronics

Die-cut VHB tapes create a precise fit for electronic devices, creating an impact resistant bond and watertight seal for thin devices that include:

Cell phones

Laptop computers

Tablets,

Cameras

Televisions

Displays

Construction

VHB tapes form a strong bond that requires no finishing. When combined with its high durability and resistance to weather conditions and temperatures, it makes an ideal bonding solution for construction materials that include:

Exterior panels stiffener attachment

Glass panes to frame

Commercial windows and doors muttin bar attachment

Skylights/canopy systems cladding attachment

Architectural cladding to frame

Gasketing and seals

Transportation

VHB tapes will wear or not loosen when subjected to constant vibration and they also act as sound dampening materials, making them ideal for truck, trailer and automotive applications. Since VHB tapes can bond to a wide variety of materials, they are often used in transportation assembly that includes:

Interior trim mounting

Exterior trim mounting

Bonding exterior panels to vehicle frames

Sidewall panel to frame for trailers

Roof bow attachment

Appliances

VHB tapes provide a more aesthetically pleasing exterior for appliances while providing excellent resistance to heat, vibration, and much more. VHB tape is commonly used in many different appliances:

Oven cladding attachment

Microwave door housing attachment

Washing machine & Dryer nameplates

Dishwasher & Refrigerator display lens

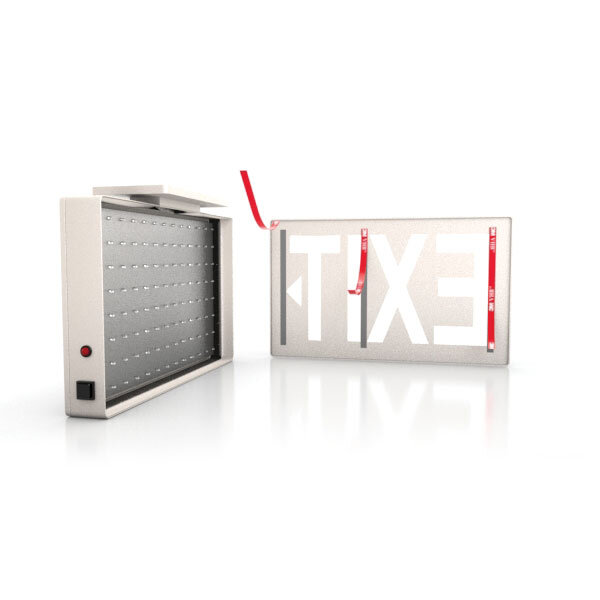

Signage

VHB tapes create a clean surface for signage and allow for joining of dissimilar materials, while creating a watertight seal that is highly resistant to the elements (as opposed to metal fasteners that can rust over time). VHB tapes can be used in any type of interior or exterior signage application that needs a long-lasting bond.

Sign panel to frame bonding

Embossed letter attachment

Decorative trim attachment

Interior sign plate mounting

Metal Fabrication

VHB tapes greatly improve productivity in metal fabrication, replacing the need for spot welding and riveting that slows down the production process. VHB tapes are easy to apply and require no finishing, leading to quick and easy assembly when working with a diverse range of metals and other materials.

Stiffener to panel bonding

Panel to frame attachment

Decorative trim mounting

Joining dissimilar substrates